Early years

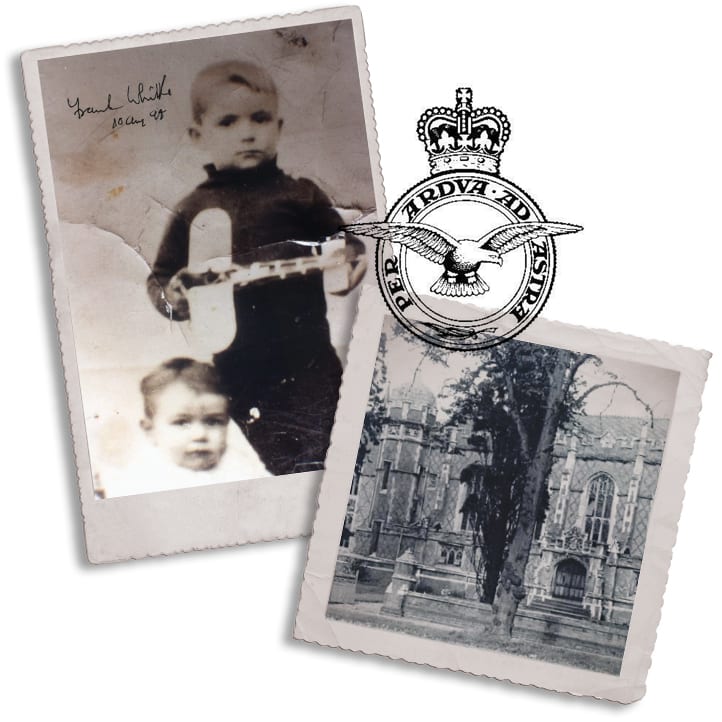

Frank Whittle was born the eldest child of Moses and Sarah Whittle in Newcombe Road, Coventry, on 1st June 1907. His father, brought up in the shadow of poverty, had left school aged 11 to work in his local Lancashire cotton mill, eventually becoming a skilled and inventive mechanical engineer and, after moving south, owning a small engineering company. Young Frank attended the local council schools before winning a scholarship to a secondary school, which later became the Leamington College for Boys. By helping his father in his workshop, he quickly developed a practical engineering knowledge.

- Frank Whittle aged 4

- Leamington College for Boys

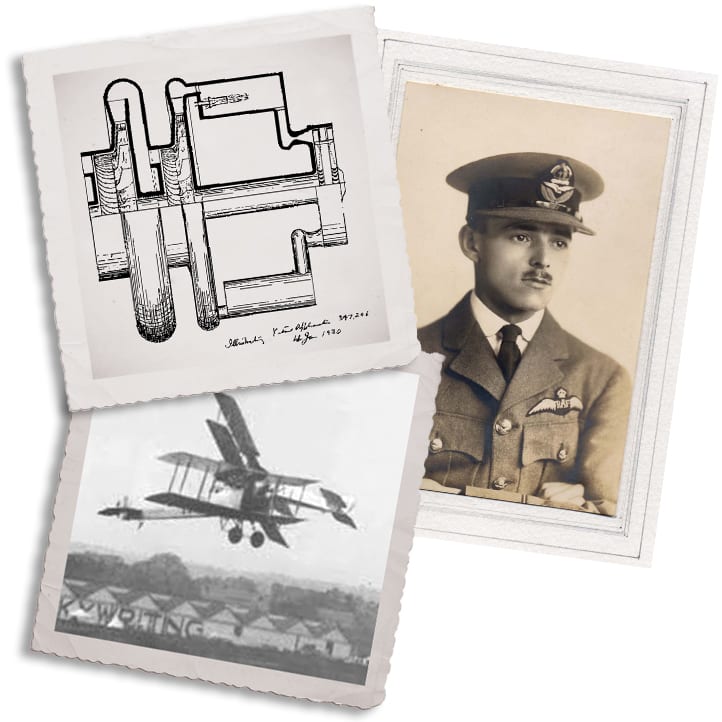

In 1926, due to outstanding qualities as an apprentice, he was awarded a cadetship at the RAF College (also at Cranwell) to train as an officer and pilot. Here he developed into something of a daredevil flyer and was, amongst other things, punished for hedge-hopping. However, before graduating he had written a thesis: “Future Developments in Aircraft Design”. In this, he considered atmospheric characteristics, the advantage of less dense air for high-speed flight and alternative means to power aeroplanes. But, most importantly, he proved by calculation that the turbine had the potential to be a prime mover for aero-propulsion. His 2-year course as a Flight Cadet ended in 1928 and he passed out with distinction – also winning the coveted Abdy Gerrard Fellowes Memorial Prize for Aeronautical Sciences. Now elevated to the rank of Pilot Officer, he was posted for a tour with No. 111 Squadron flying the Siskin bi-plane fighter. Following this happy interlude, he moved to the Central Flying School (CFS) in 1929 to qualify as a flying instructor.

- 1929 proposal

- Frank Whittle, Pilot Officer

- Whittle demonstrates crazy flying during an RAF pageant at Hendon

During his spare time on the squadron and at CFS he gave much thought to the application of the internal combustion turbine as a means to drive the aeroplane propeller. As others had before him, he soon discovered that the levels of component efficiency in any suitable gas turbine engine would be dauntingly difficult to achieve. And then, as he would say in later life, “the penny dropped” and he perceived the possibility of using the high velocity/high mass flow exhaust to obtain propulsion by reaction. In doing so, he was dismissing the altitude limitations of the internal combustion engine and the speed limitations of the propeller. A practical form of turbojet was borne. An entirely new horizon for aeronautics was about to materialize.

Whittle worked on the business of the design of an engine with a potential thrust sufficient to propel a small aeroplane at very high speeds and at very high altitudes. He settled on an arrangement that incorporated a two-stage centrifugal compressor and a two-stage (Curtis) turbine. He estimated a compression ratio of 4:1 and a rate of combustion of liquid fuel of about 168 imperial gallons per hour with a temperature at the turbine inlet of 800º K.

He showed his idea to the station commandant, Group Captain Baldwin, who, perceiving strategic importance and a need for secrecy, sent him to be interviewed by the engine division at the Air Ministry. They in turn, arranged for him to meet Dr A A Griffith at the Royal Aircraft Establishment (RAE). Griffith had started seriously considering gas turbines for propeller-driven aircraft as early as 1926. In a meeting of considerable consequence, Griffith rejected Whittle’s proposals and convinced the Ministry that the idea did not warrant any further attention. Unfortunately, Griffith had his own agenda. He would have known full well that he would be instructed to work on the turbojet should he admit any serious practicality. Despite this setback, Whittle went ahead and applied for a patent – granted in January 1930. However, as the President of the Air Council declared that there was no need for secrecy, it was published in 1931. Copies were purchased by, amongst others, the German Trade Commission in London. It was then circulated by technical journal to the German Air Ministry (RLM), aero-engine and airframe manufacturers and, most significantly, to the research establishments. Unfortunately the patent lapsed in January 1934 because Whittle could not afford the extension fee and the Air Ministry declined to help. In the mean time, the Germans added the turbojet to the list of alternative forms of aero-propulsion under scrutiny in their country: Rocket, pulse-jet, turbo-prop, ducted fan jet and ramjet

After a stint as a Flying Instructor at No. 2 Flying Training School, Whittle became a test pilot – involved with numerous tasks including the deliberate ditching in the sea of redundant aircraft, and catapult development for float-planes. All rather hazardous for a person who was unable to swim!

Further education

- Sir Frank Whittle, top row centre, began his theoretical work on jet propulsion while at RAF Cranwell. Photo Alastair Stewart

- In 2004 a blue plaque was erected at the entrance to Cambridge University Department of Engineering.

- Whittle, staff member, fellow apprentice

Some idea of the problems involved can be obtained by comparing his concept with the then state of the art. For instance, the compressor (now a single-stage double sided component) would need to shift over ten times as much air and deliver it at twice the pressure of current superchargers. The combustion chambers would require a combustion intensity many times that so far achieved in any boiler furnace and (now) a single-stage turbine of only 400 mm diameter would need to develop adequate horsepower to drive the compressor. Whilst finding solutions to these problems, promoting his ideas, seeking out suppliers and starting a development programme, he completed his Tripos and gained a First – all in 2 years. Permitted a further year at Cambridge for ‘post graduate research’, Whittle was subsequently placed on the Special Duties List to allow further continuity in the supervision of component manufacture and the building of his engine. Known as the WU, the engine first ran successfully at the British Thompson-Houston (BTH) works at Rugby on 12th. April 1937.

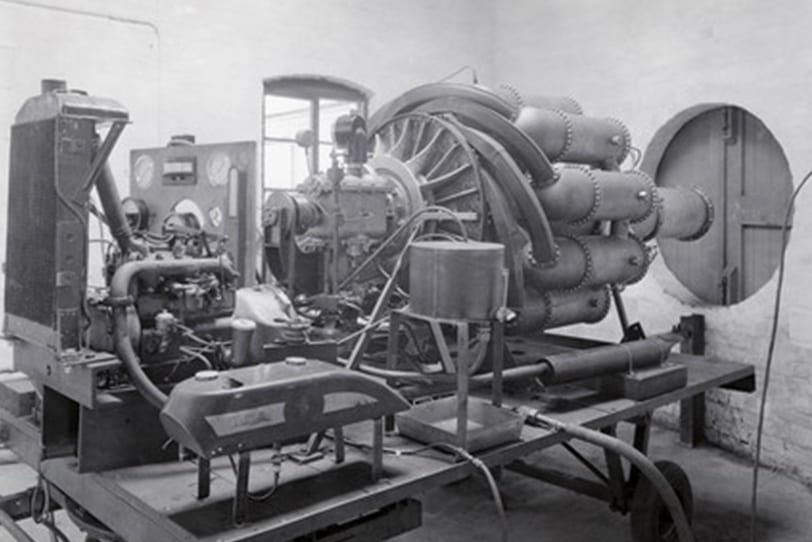

Original version of Frank Whittle's first experimental bench test engine, the Power Jets W.U., with its starting panel, circa April 1937

Painting by Rod Lovesey

The original WU engine, after its second rebuild, ready for testing at the Ladywood Works

One of the early combustion test rigs, using a barrel of white spirit at the BTH facility at Ladywood

Move to Lutterworth

- Bust of Frank Whittle Memorial Gardens, Lutterworth

- Frank Whittle Memorial Roundabout, Lutterworth

The rebuilt engine was delivered in September 1938 just as the finances of Power Jets were at a critical condition. With engine performance well below theoretical estimates, Whittle began to show signs of the strain. And, to further complicate matters, he was warned that he might be returned to regular service as the military was then on a state of emergency. A skilful and highly experienced pilot, he would clearly have been well able to take his part in the oncoming fray. However, tests of the rebuilt engine were looking promising until fracturing occurred on the tips of the impeller blades. Replacement resulted in a further delay of almost 2 months with testing resumed on 17th June 1939. The engine was soon reaching speeds of 16,000 rpm – much higher than any achieved previously.

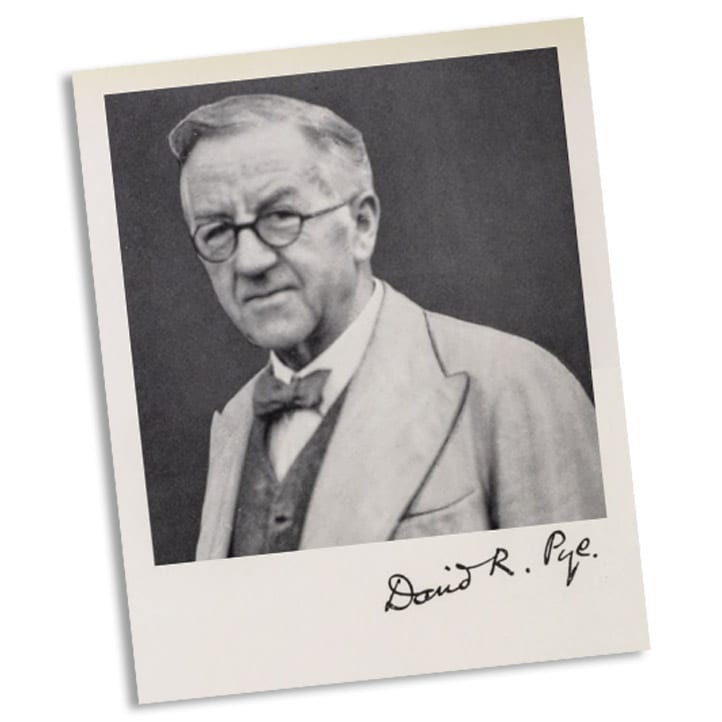

- Dr Pye, the Director of Scientific Research

The vulnerability of Power Jets

Development problems

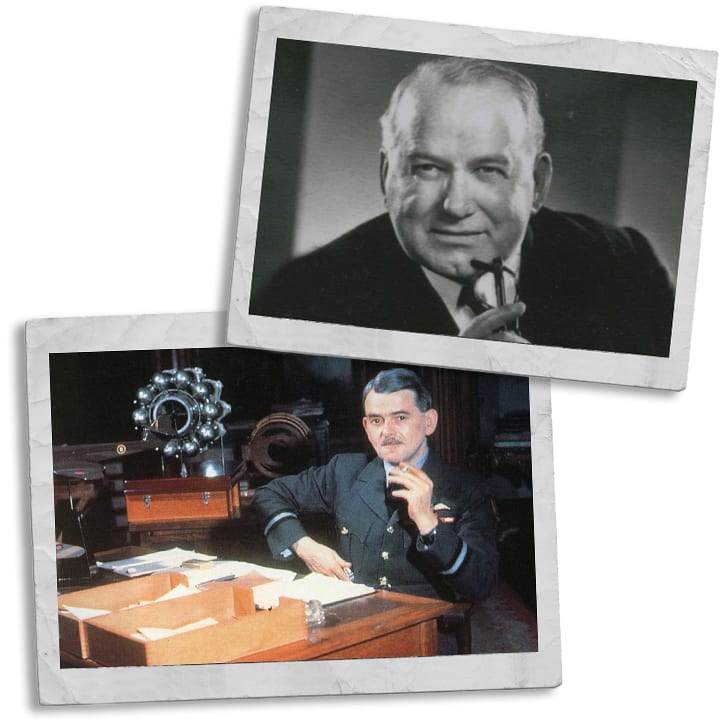

- Air Vice-Marshall Tedder, Director-General of Research and Development

- A Rover-built W2B reverse flow engine

During 1940 it had become obvious that Power Jets needed more office space. There had been an influx of boffins, many billeted on local households, with some working on the stairs near Whittle’s office. An old disused railway carriage parked on a nearby siding became the office of the combustion engineers. Rooms were rented at Brownsover Hall, a large historical house on the northern edge of Rugby. Whittle moved his office there, taking with him his senior design staff. But the main drawing office remained located in a large wooden hut at the Ladywood Works. In October 1941 the government ordered a greatly enlarged design and development facility some 7 miles further up the road at Whetstone, to open in 1943.

The Gloster E28/39

- The E28/39 shown over Cranwell on its first flight, artist Kenneth McDonough

- Wing Commander Whittle congratulates the test pilot Flt. Lt. Gerry Sayer after the first flight

Although rated at 1,240lb, the W1 was de-rated at 860lb for the first few flights as a means to moderate the temperature at the turbine.

Sir Frank Whittle and Hans von Ohain

(L-R) Erich Warsitz (Test Pilot), Ernst Heinkel, Hans von Ohain

Sir Frank Whittle and Hans von Ohain

Sir Frank Whittle aeronautical engineer and inventor of the jet engine, gives instructions in its workings to the journalist Clifford Troke, 1948.

- Whittle, in uniform, and its designer George Carter, far right, in front of a Meteor I

- The Derwent-powered Meteor was produced in large numbers and fulfilled many roles

The Derwent had a similar level of thrust to the next and final Whittle development, the W2/700. In effect, the two engines became competitors. But R-R were happy to move on from the reverse-flow combustion system of the Whittle engine and follow their own initiatives. Ernest Hives suggested that Rolls-Royce and Power Jets should link up, but whilst Whittle thought that a true development partnership should be possible, Hives made it clear that Rolls-Royce would never take orders from Power Jets. With Rolls-Royce now in control of Barnoldswick and with Whittle’s health deteriorating, it was Hives who let the opportunity pass on this occasion.

- Lord Hives, Chairman & Managing Director, Rolls-Royce

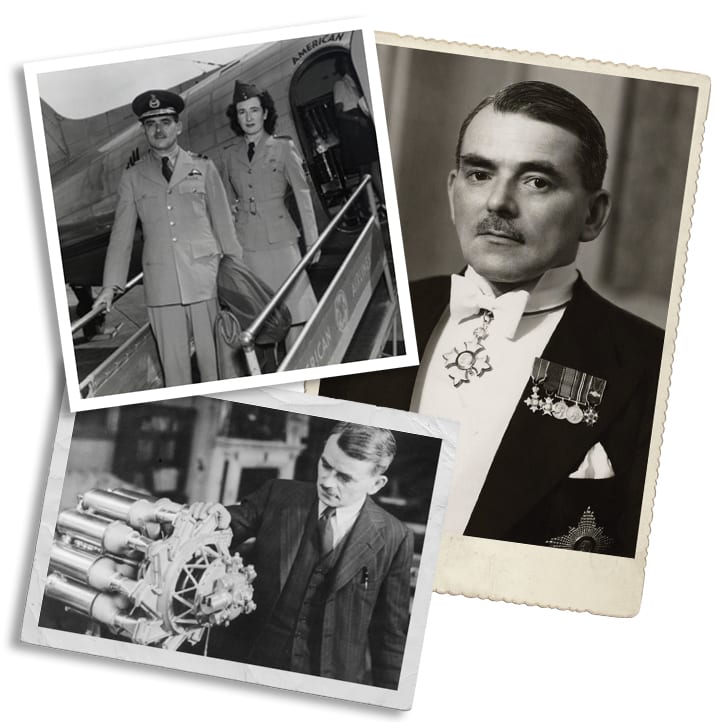

- Air Commodore Whittle c1946.

Public recognition – but the end of Power Jets

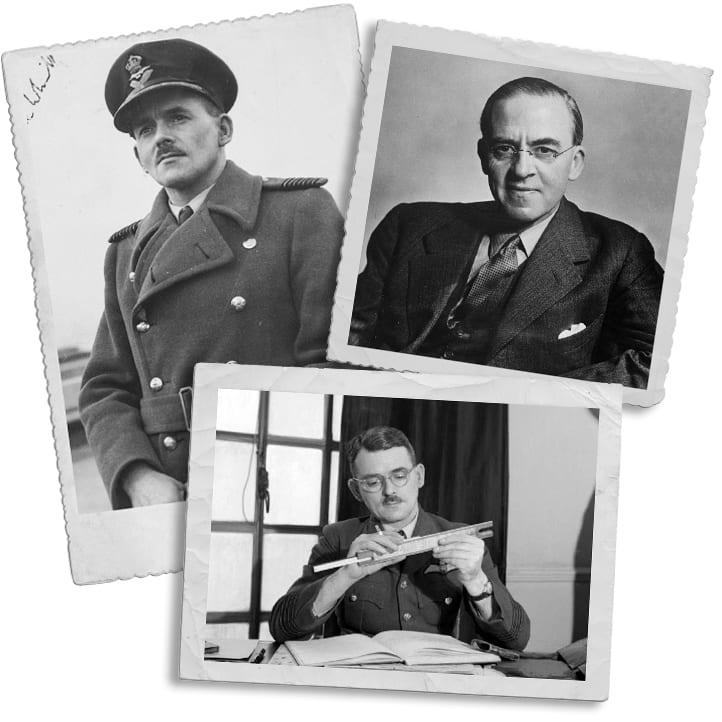

- Group Captain Frank Whittle in 1944

- Sir Stafford Cripps, Minister of Aircraft Production

- Whittle working with his trusty slide rule (No compact electronic computers in those days!)

- Frank Whittle and his fellow directors

Moreover, Rolls-Royce objected strongly to Power Jets (R&D) even building prototype engines. Further development of the W2/700 had been under way and work was proceeding on some important innovations: The first high-bypass turbo-fan engine (LR1) and the first after-burner (re-heat) with an aft fan system applied to the W2/700. These radical improvements to the basic turbojet had been foreseen by Whittle at some point before the end of 1933 – with patents filed in 1936. The aft fan version of the W2/700 with after-burner was intended to power the Miles M.52 experimental aircraft – predicted to attain a supersonic speed of 1,000 mph (1,600 kph). For reasons associated with political and industrial pressures the government subsequently cancelled all these innovative projects – including the M.52. Nearly twenty years would go by before GE stepped in with their first high-bypass turbo-fan engine. Rolls-Royce sat up and soon followed suit.

In October 1945, Whittle was at last able to make a flight in a Meteor 1 powered by engines he had himself designed – the W2/700. A few days later, he flew a Derwent-powered Meteor III. In January1946, disillusioned by events, he resigned from Power Jets (R&D) Ltd and reverted to normal duties with the RAF. The company was later merged with the gas turbine section of the Royal Aircraft Establishment and consolidated into the National Gas Turbine Establishment (NGTE) at Farnborough. Most of the small band which Whittle had built up – henceforth to be known as “The Reactionaries” and to meet informally once a year for the next fifty-odd years – dispersed a few weeks later to pursue separate careers in industry.

- Air Commodore Whittle with Lt Shepherd taken in the USA at McDonnell Corporation

- In 1948 Frank Whittle was knighted by King George VI

- With a ¼ -scale model of a W2/700